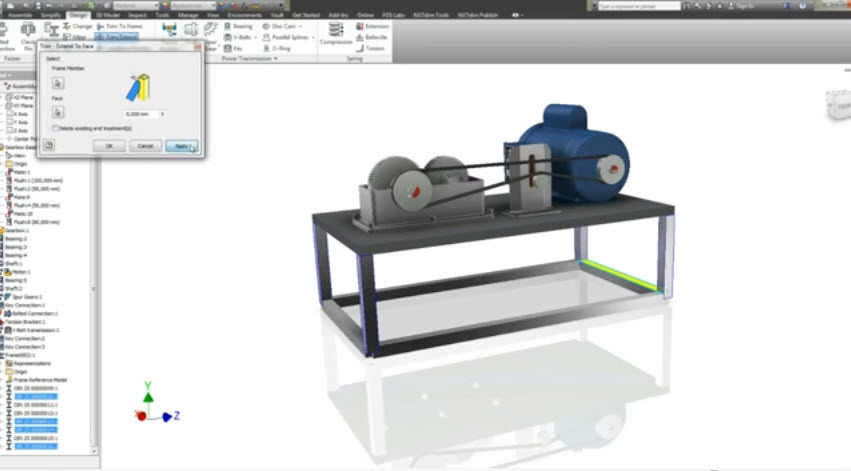

Robert Reid graduated from Middlesex College in New Jersey with a Degree in Mechanical Engineering Technology. The Red Arrow in the middle can be used to drag the key around the shaft to any angle.ġ2) Change key length from 50mm to 63 mm:ġ4) Change Power to 7.5kW, and Speed to 260 RPM:ġ5) Key Material will be Surface Hardened Steel:ġ6) Click Calculate! We are within Design Compliance meaning the strength of the Key Connection meets our design parameter criteria!Ĭlick the Design Tab, Click OK, Click Ok to File Naming, Our Keyed Connection is added into our Assembly along with the Key, Shaft Groove, Hub Groove! In the following image, note the Red Arrow Grips! The ones on the end with the 2 arrows can be used to drag the length of the key to make it longer or shorter. Inserts Key, Inserts Shaft Groove, and Inserts Hub Groove: In this example, we will select the circular edge of the hub to start the key groove:ġ1) For Objects to Generate, we will select all 3: In this example, we will select the Face of the Gear Hub:ġ0) For Reference 2, we need to select a Circular Edge or Work Point: In this example, we will select the Green Face of the Shaft:ĩ) For the Hub Groove, Reference 1, we need to Select a Planar Face or Work Plane: In this example, we will select the Red Circular Face of the Shaft:Ĩ) For Reference 2, we need to select a Planar Face or Work Plane (Other choices would be: Groove with 1 Rounded End or Plain Groove)ħ) For Reference 1, we need to select a cylindrical face: We will design the key to be strong enough to transmit 7.5 kW of Power at 260 RPM:ġ) Gear/Shaft is assembled in a “Saved” Assembly File.Ģ) Click on the Design Tab to access the Design Accelerator:ģ) Click on Key, on the Power Transmission Panel:Ĥ) This will open the Parallel Key Connection Generator:ĥ) 1-Under Key, Select what type of Key to use, for this example, we will choose theĦ) For Shaft Groove, we will choose: Groove with Rounded Ends: In the following example, we will insert a key to connect the gear to the shaft. Select the calculation method or type of strength calculation in the Calculation tab.

Enter information in Design tab to design a key without calculation.In the Parallel Key Connection Generator: After you enter the shaft diameter, the corresponding key is selected as well as the shortest length that can carry the required load. Parallel Key Connection Concept: Designs key joints and performs strength checks. Generators and calculators are grouped according to functional areas, for example, all welds are grouped.

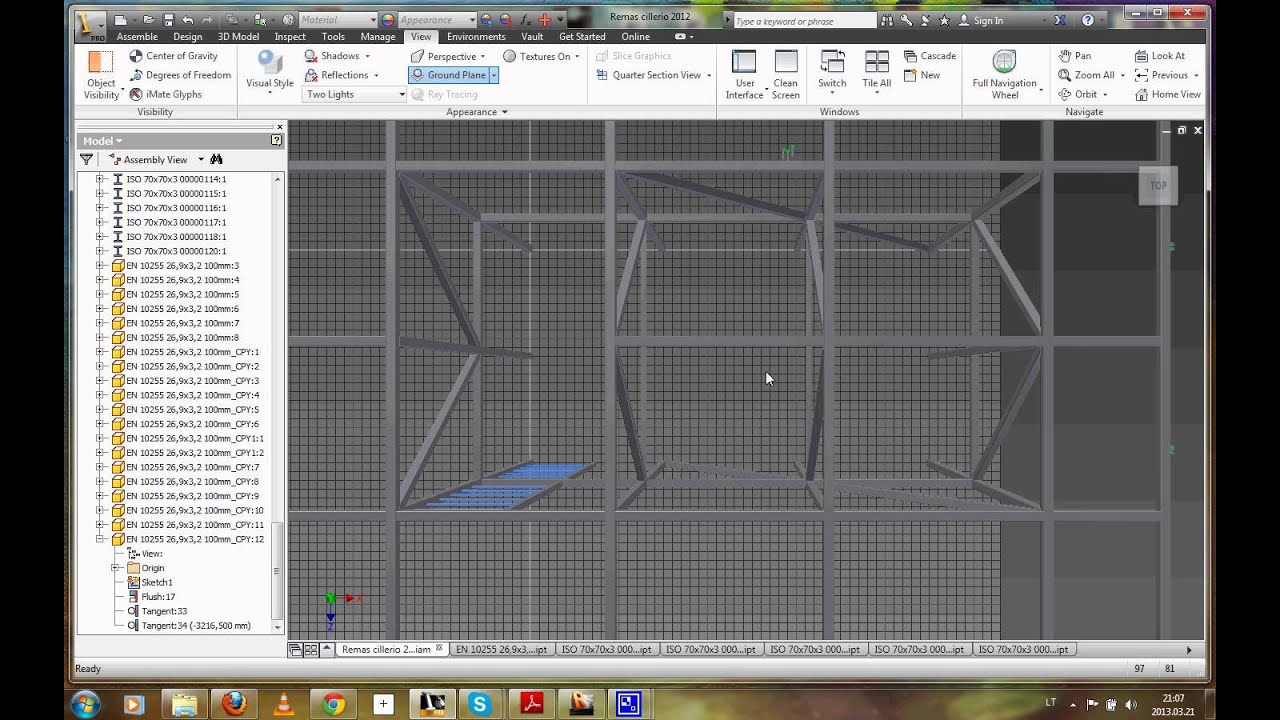

The available generators and calculators commands are displayed. To insert components using Design Accelerator generators and calculators, work within the assembly or weldment environment.

Autodesk inventor 2013 key generator generator#

For example, use the bolted connection generator to insert a bolted connection at once by offering to select the right parts, select holes, and assemble components together. They automate the selections and geometry creation, improve initial design quality by validating against design requirements, and increase standardization by selecting the same components for the same tasks.ĭesign Accelerator provides a set of generators and calculators that can create mechanically correct components automatically by entering simple or detailed mechanical attributes. The Design Accelerator commands simplify the design process. It provides engineering calculation and decision support to identify standard components or create standards-based geometry. Using functional design, you can create mechanically correct components automatically by entering simple or complex mechanical attributes.ĭesign Accelerator Definition: The Design Accelerator represents an important component of Functional Design. It supports design by function and adds mechanical content and intelligence. Januby Robert Reid, Manufacturing Solutions Engineer:įunctional Design Definition: Functional design is a knowledge content tool that represents the trend to move from geometrical descriptions to capturing knowledge.ĭesigners use functional design to analyze the function of their products and the design problems they are trying to solve, rather than spending time on the modeling operations necessary to create 3D representations.įunctional design is not only a set of functions.

0 kommentar(er)

0 kommentar(er)